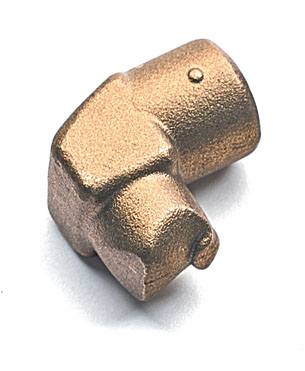

FORMING

Cold Extrusion – Forging

Either through intense pressure or a combination of

pressure and temperature, it is possible to fabricate

complex components which are so precise, with such an

excellent surface finish, that they can be used without any

further processing.

In addition to (closed die) forging, in which the glowing

hot workpiece is shaped as quickly as possible through

hammer strikes, in cold extrusion, the material is caused

to flow in a cold state and is formed by the construction

of the moulds.

A particular advantage of this is the consistent

part tolerance. Further advantages are the cold work

hardening of the material, which improves the quality of

the workpiece, and the relatively low material input.

Together with our clients, we attempt to find the optimal

process for each application.

English (EN)

English (EN)